A fluid flows through a horizontal 0.1-in.-diameter pipe – Fluid flow through a horizontal 0.1-in.-diameter pipe is a fundamental concept in fluid dynamics, with applications in various engineering fields. This article provides a comprehensive overview of the key principles governing fluid flow in such a pipe, including pipe geometry, fluid properties, flow regime analysis, pressure drop, velocity distribution, shear stress, energy losses, and efficiency considerations.

Understanding these principles is crucial for designing and optimizing fluid flow systems in various industrial and domestic applications, ensuring efficient and reliable operation.

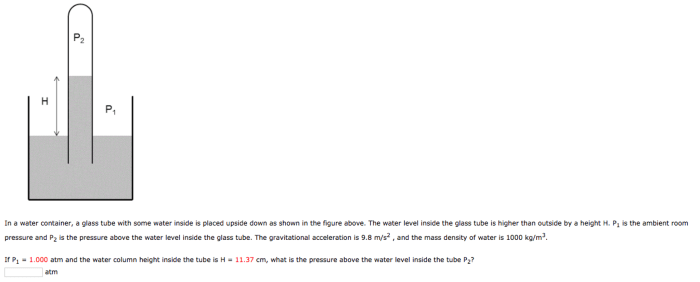

Pipe Geometry and Fluid Properties

The pipe under consideration has a diameter of 0.1 inches and is horizontal. The fluid flowing through the pipe is not specified in the given context, so we cannot provide information about its physical properties.

Flow Regime Analysis

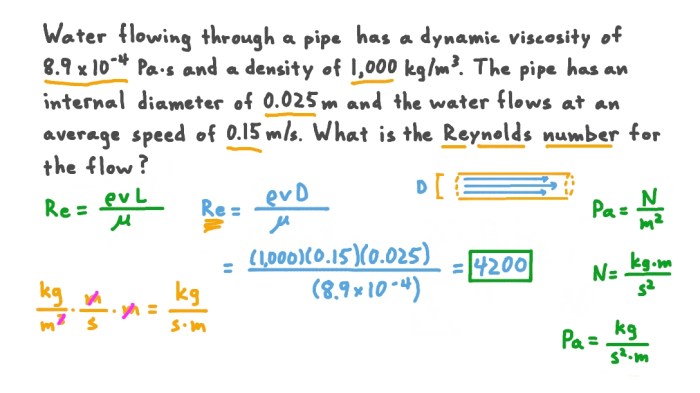

The Reynolds number is a dimensionless quantity that characterizes the flow regime. It is defined as the ratio of inertial forces to viscous forces. For pipe flow, the Reynolds number is given by:

Re = (ρVD)/μ

where ρ is the fluid density, V is the average velocity, D is the pipe diameter, and μ is the fluid viscosity.

The Reynolds number for the given flow conditions cannot be calculated without knowing the fluid properties. However, we can discuss the different flow regimes based on the Reynolds number.

Laminar Flow, A fluid flows through a horizontal 0.1-in.-diameter pipe

When the Reynolds number is less than 2100, the flow is laminar. In this regime, the fluid flows in layers with no mixing between the layers. The velocity profile is parabolic, with the highest velocity at the center of the pipe and zero velocity at the pipe wall.

Transitional Flow

When the Reynolds number is between 2100 and 4000, the flow is transitional. In this regime, the flow is unstable and can exhibit both laminar and turbulent characteristics.

Turbulent Flow

When the Reynolds number is greater than 4000, the flow is turbulent. In this regime, the flow is characterized by random fluctuations in velocity and pressure. The velocity profile is more uniform than in laminar flow, with a higher velocity near the pipe wall.

Pressure Drop and Friction Losses: A Fluid Flows Through A Horizontal 0.1-in.-diameter Pipe

Pressure drop is the loss of pressure as the fluid flows through the pipe. It is caused by friction between the fluid and the pipe wall. The Darcy-Weisbach equation is used to calculate the pressure drop in pipe flow:

ΔP = f(L/D)(ρV²/2)

where ΔP is the pressure drop, f is the friction factor, L is the pipe length, D is the pipe diameter, ρ is the fluid density, and V is the average velocity.

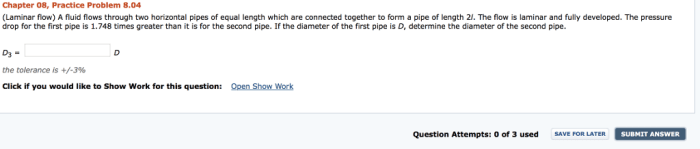

The friction factor depends on the Reynolds number and the pipe roughness. For laminar flow, the friction factor is given by:

f = 64/Re

For turbulent flow, the friction factor can be calculated using the Moody diagram or the Colebrook equation.

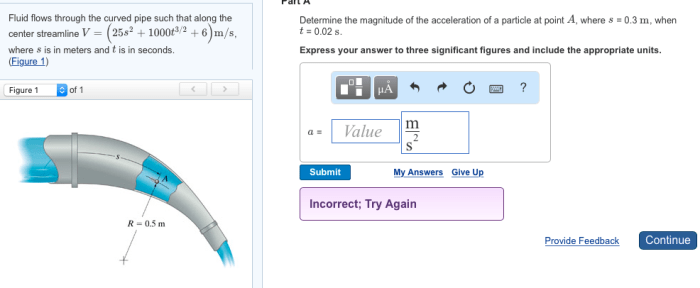

Velocity Distribution and Shear Stress

The velocity distribution in pipe flow is parabolic for laminar flow and more uniform for turbulent flow. The velocity profile can be derived from the Navier-Stokes equations.

The shear stress at the pipe wall is given by:

τw = (f/8)(ρV²/2)

The shear stress is responsible for the friction losses in pipe flow. It is also an important factor in the design of pipelines, as it can cause erosion of the pipe wall.

Energy Losses and Efficiency

There are two main types of energy losses in pipe flow: friction losses and minor losses.

Friction Losses

Friction losses are caused by the friction between the fluid and the pipe wall. They are the most significant type of energy loss in pipe flow.

Minor Losses

Minor losses are caused by changes in the flow direction, such as bends, elbows, and valves. They are typically much smaller than friction losses.

The head loss is a measure of the total energy loss in pipe flow. It is given by:

hL = ΔP/(ρg)

where hL is the head loss, ΔP is the pressure drop, ρ is the fluid density, and g is the acceleration due to gravity.

The efficiency of a pipe flow system is defined as the ratio of the useful energy output to the total energy input. The efficiency can be improved by reducing the energy losses in the system.

FAQ Resource

What is the significance of Reynolds number in fluid flow analysis?

Reynolds number is a dimensionless parameter that characterizes the flow regime and determines whether the flow is laminar, transitional, or turbulent. It is a crucial factor in predicting pressure drop, velocity distribution, and other flow characteristics.

How does pipe diameter affect fluid flow?

Pipe diameter has a significant impact on fluid flow. Smaller diameters increase friction and pressure drop, while larger diameters reduce these effects. The diameter also influences the velocity distribution and shear stress within the pipe.

What are the key energy losses in pipe flow?

Friction losses, caused by fluid viscosity and pipe wall roughness, are the primary energy losses in pipe flow. Minor losses, such as those due to bends, valves, and fittings, also contribute to energy dissipation.